IATF 16949, Encompassing ISO 9001 Certified Machine Shop in PA, OH, MI

PHB Machining is a high capacity 158,000 sq. ft. facility capable of CNC machining augmented by feedback on die casting integrity by being located next to a die casting plant. Our contract machining services allow for casting and machining simultaneously with help from careful planning and scheduling to offer short lead times and a high degree of customization.

We are an IATF 16949, encompassing ISO 9001, certified machine shop with 130 dedicated employees that run three different shifts. With that kind of quality assurance, you can approach your CNC machining projects with confidence knowing that our team abides by an unrelenting company quality policy. Take a closer look at what sets PHB apart.

Why Choose PHB for Close Tolerance CNC Machining?

When you need close tolerance CNC machining services, PHB offers a wide range of benefits you can enjoy.

- Our large facility and staff allows for high volume production and quick turnaround.

- Our testing and quality assurance processes ensure the highest quality products.

- We provide cost-effective solutions to short run productions.

- We are an ITAR compliant contract machining manufacturer.

IATF 16949 Certification

The IATF 16949 certification is a widely used international standard for quality management and supersedes the ISO 9001 certification. While we were formerly ISO 9001 certified, we have since adopted the use of the IATF 16949 standard in our quality management systems and operations. This standard was born from the basis set by ISO 9001 in that it follows the same process-focused approach to examining quality management of every member of the automotive supply chain. That includes design, production, and even installation and mechanical service when necessary.

One of the most important aspects of IATF 16949 certification is that it identifies those who fulfill customer-specific requirements instead of solely bolstering the quality management system. With that in place, you can turn to PHB with confidence knowing that our CNC machining efforts will meet your unique specifications. Overall, this certification represents our adherence to a widely accepted standard that focuses on preventing errors from occurring in the first place rather than discovering them.

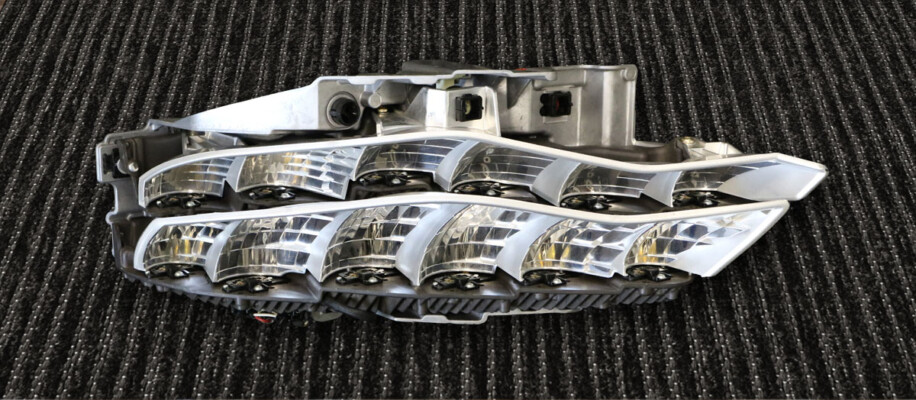

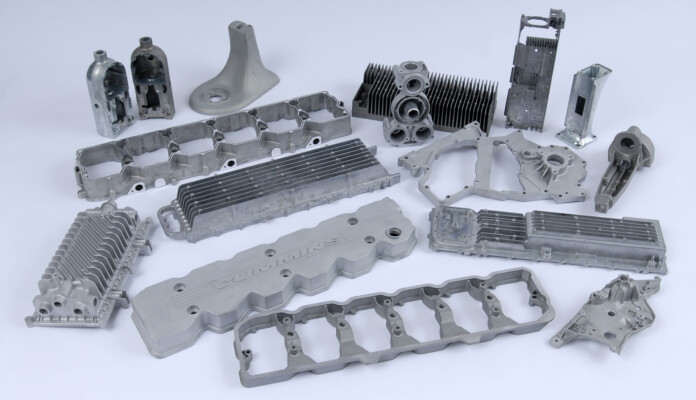

Precision Aluminum & Zinc Cast Machining

Close tolerance CNC machining capability from PHB Machining offers turning, mining, drilling, boring, and tapping. Our team can handle assembly and impregnation as well using Imprex 95-1000A resin. With state-of-the-art equipment like 10 CNC lathes, 27 CNC horizontal machine centers, 12 vertical machine centers, and a 28-station Palletech System we can manufacture parts up to 36” in diameter at spindle speeds up to 18000 rpm.

PHB uses a Quality Assurance Lab to ensure that all products shipped from our facility meet your standards for both low and high volume CNC machining productions. This quality assurance includes 4 coordinate measuring machines, which handle in-process checks, first piece layouts, PPAPs, and quarterly statistics. Our Millipore testing services can additionally test the cleanliness of parts manufactured.

Aluminum Casting Impregnation

At PHB, we offer aluminum casting impregnation services entirely in-house. These services are designed to reduce shrink porosity and gas porosity, which could compromise the specifications of a design leading to product failure. Our impregnation process is fast and effective using a vacuum chamber and resin drawn through the casting to fill any porosity voids. This will lead to no change in appearance or dimensions of the final product, and castings at PHB can be impregnated as cast or finish machined.

Leak Testing

Our facility offers complete leak testing capabilities entirely in-house for customers who need this value added service. We have experience performing leak testing on a wide range of materials and products of varying sizes. Our capabilities include the following.

- Water Submersion

- Pressure Decay

- Mass Flow

- Vacuum Decay Methods

Our test equipment is state-of-the-art and manufactured by Cincinnati Test Systems and Testra/Unson. Currently, we have 20 dedicated test centers and 2 universal systems. Our facility is capable of multi-stage testing, and all our fixturing is designed and manufactured in-house.

Millipore Part Cleanliness Testing

To monitor part cleanliness, PHB utilizes an in-house Millipore Lab. It’s fully equipped with supplies to bolster Millipore cleaning, collecting, and making use of a positive flow ventilation hood. We additionally use a solvent in the testing process that is friendly to both the environment and to our operators. Customer requirements are validated on an audit basis to ensure compliance.

Our diversified supplier base allows us to offer a range of other services too including the following:

- Plating

- Painting

- Mag Particle Inspection

- Heat Treating

Choose PHB for Comprehensive Quality CNC Machining Solutions

PHB Machining is an IATF 16949, encompassing ISO 9001, certified machine shop offering manufacturing services in PA, OH, and MI. Request a quote from our team today for high quality CNC machining solutions.

[/wpv-noautop]