Casting Sourcing & Casting Machining for Sand Castings & Permanent Castings

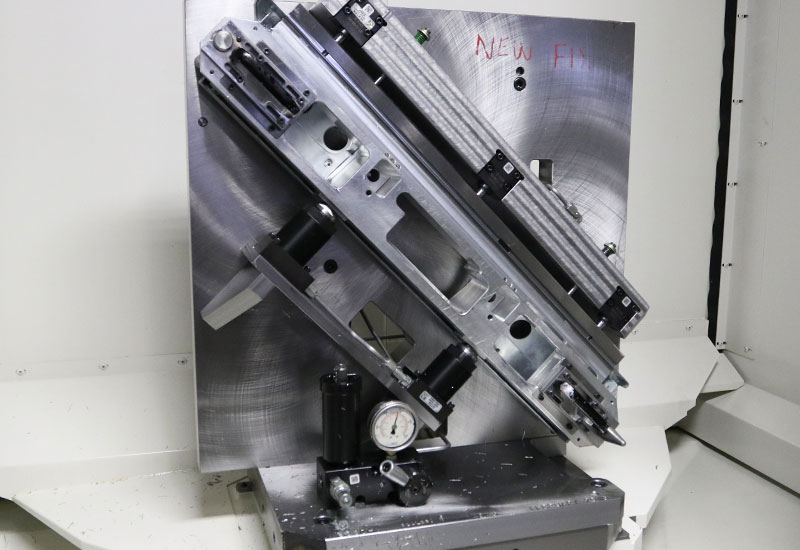

- Our large facility and staff allow for non-die cast, high volume CNC machining production and quick turnaround.

- Our testing and quality assurance processes ensure the highest quality non-die cast CNC machined products.

- We provide cost-effective solutions to short run production for all non-die cast CNC machined parts.

Our team of experienced employees are what differentiates PHB from the competition. With over 130 dedicated employees running three shifts, we focus on our company policy of meeting customer requirements and continually improving non-die cast CNC machined products.

Choose PHB as Your Casting Procurement & Casting Finishing Resource

We at PHB are experts in casting sourcing and finishing. We can source your sand castings, permanent mold castings, or other types of castings, and then provide close tolerance CNC machining capability in turning, milling, drilling, boring, and tapping with for materials ranging from aluminum, zinc, iron, copper, and more. Our procurement specialists can provide you with the best castings and all of the secondary operations to produce a finished part. With our die cast CNC machining services, we also offer assembly and impregnation using Imprex 95-1000A resin, verified through our leak test capability. We offer a vast array of CNC lathes, CNC horizontal machine centers, and vertical machine centers. Our machines have the capability to manufacture parts up to 36″ in diameter. With our coordinate measuring machines, we ensure that our process meets customer standards.

Sand, Permanent & Other Types of Casting Sourcing & Machining

Sand Casting Supplier | Casting Machining & Sourcing

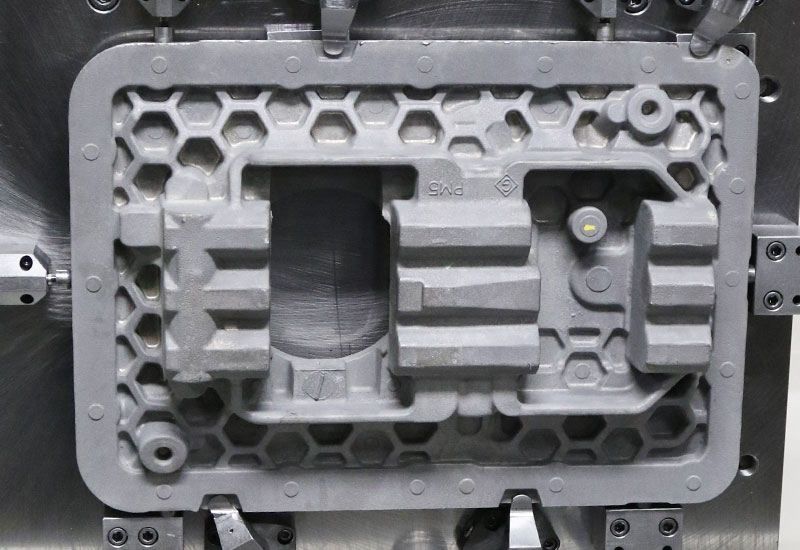

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must be destroyed in order to remove the part (also known as the casting), sand casting typically has a low production rate. The sand casting process involves the use of a furnace, metal, a pattern, and a sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed.

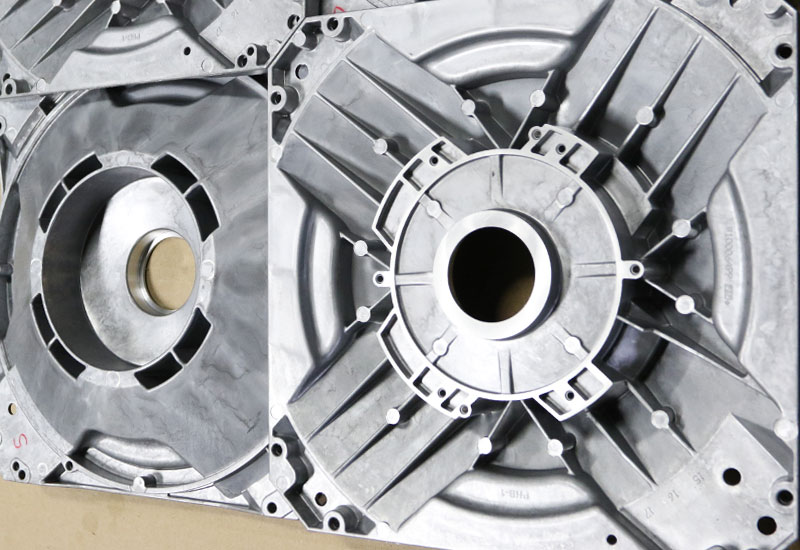

Permanent Mold Casting Sourcing and Machining

Permanent mold casting is a metal casting process that shares similarities to both sand casting and die casting. As with sand casting, molten metal is poured into a mold which is clamped shut until the material cools and solidifies into the desired part shape. However, sand casting uses an expendable mold that is destroyed after each cycle. Permanent mold casting, like die casting, uses a metal mold (die) that is typically made from steel or cast iron and can be reused for several thousand cycles. Because the molten metal is poured into the die and not forcibly injected, permanent mold casting is often referred to as gravity die casting.

Permanent mold casting is typically used for high-volume production of small, simple metal parts with uniform wall thickness. Non-ferrous metals are most commonly used in this process, such as aluminum alloys, magnesium alloys, and copper alloys; however, iron and steel can also be cast using graphite molds. Common permanent mold parts include gears and gear housings, pipe fittings, and other automotive and aircraft components such as pistons, impellers, and wheels.

Investment Casting Supplier | Vaccum Casting Machining & Sourcing

Investment castings, which are often referred to as lost-wax castings, are metal parts that are produced by the investment casting process. This expendable mold process (along with the components it produces) is extremely popular for countless applications in numerous industries. This is largely due to the fact that the investment casting process makes it possible to create complex parts with exceptional surface quality and accuracy in a wide range of materials and sizes. However, if a part requires intricate details or undercuts, the material is reinforced by fiber or wire. If air entrapment is a problem, a specific type of investment casting method is used. This investment casting technique is none other than the vacuum casting method, which produces vacuum castings.

Vacuum castings are the metal parts that are produced by the vacuum casting method. They are different than typical investment castings due to the technique that is used to create these metal parts. The process begins by placing a two-piece mold in a vacuum chamber. The vacuum then draws the molten metal into the mold. Finally, the casting is solidified in an oven and the mold is removed in order to release the final product.